Valveworks Usa Products

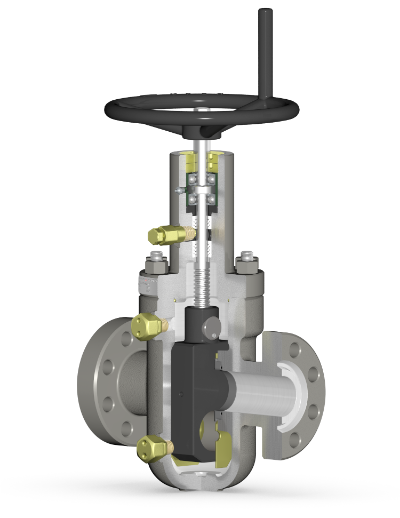

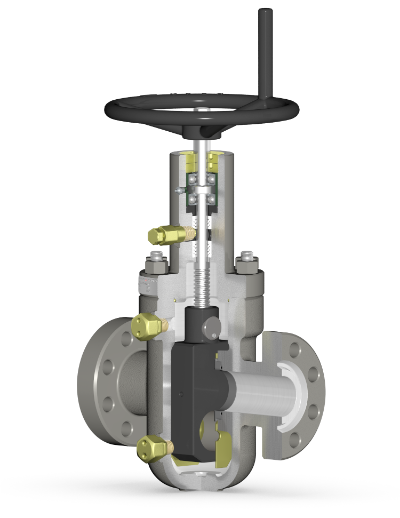

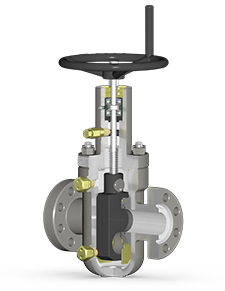

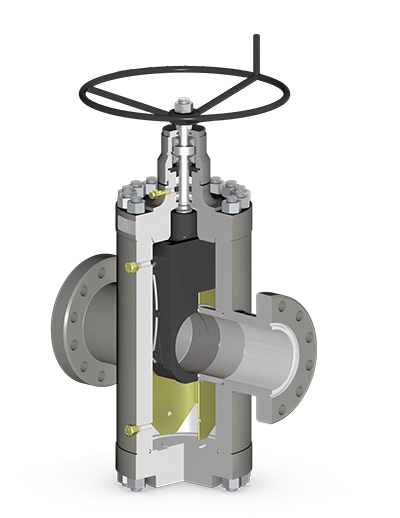

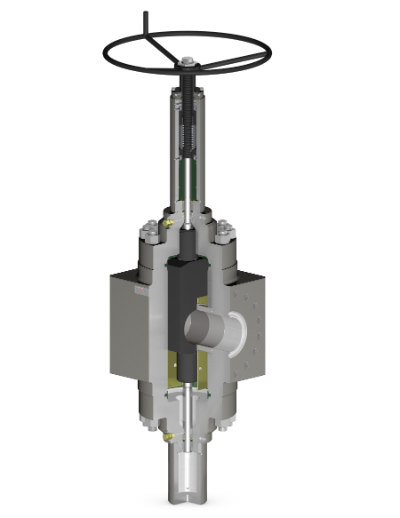

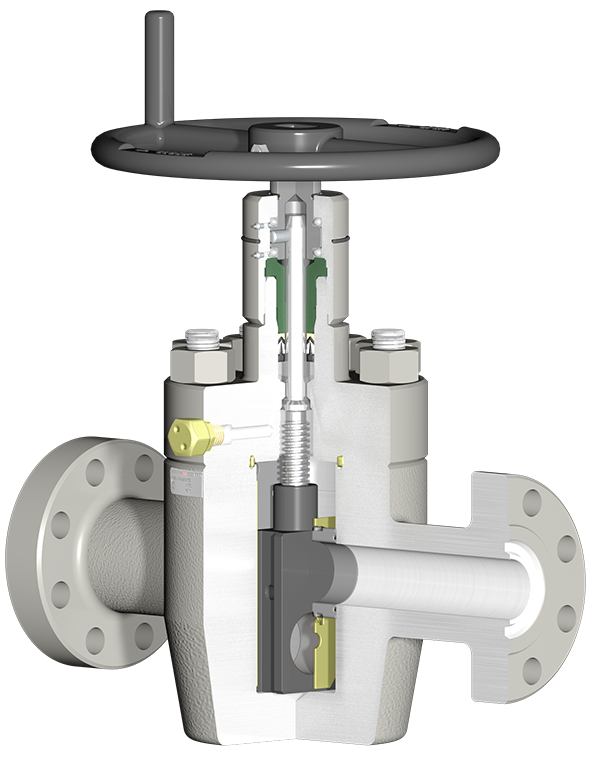

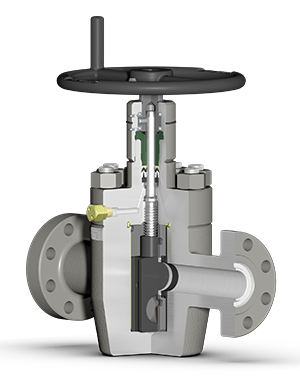

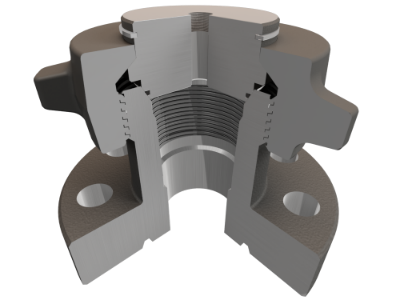

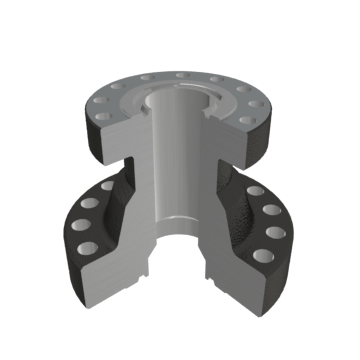

Gate Valves

In addition to Valveworks USA’s extensive inventory of in-stock gate valves, our team of highly specialized and qualified engineers work diligently to ensure that your custom needs and orders are seen through to completion. With state-of-the-art software and equipment, our engineers are capable of designing and building the most complex valves needed to fit your specific requirements, designs, and applications.

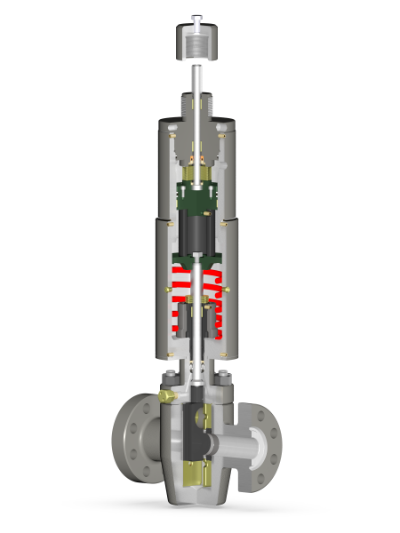

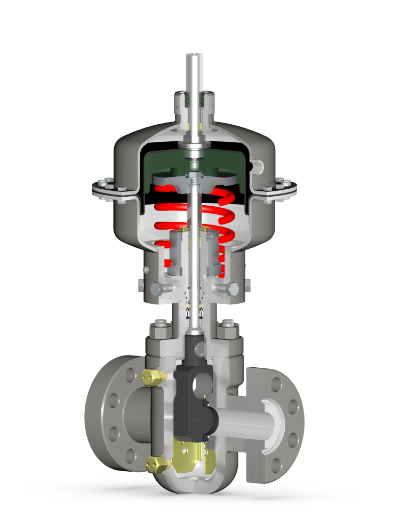

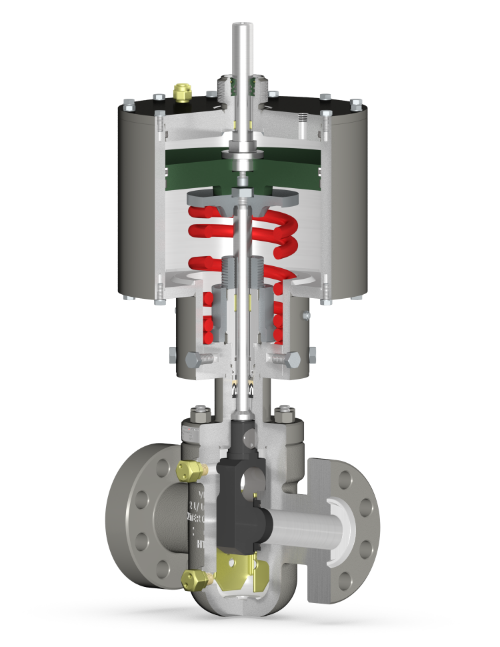

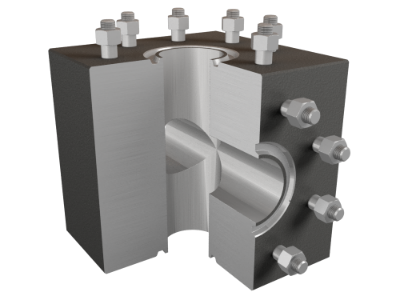

Actuators

Valveworks USA offers hydraulic and pneumatic actuators for valves from sizes 1 13/16″ to 7 1/16″ and up to 15,000 psi.

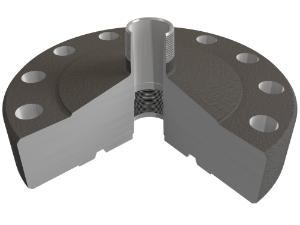

Choke Line

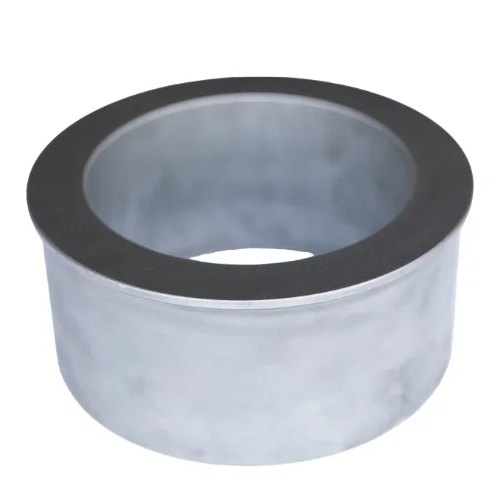

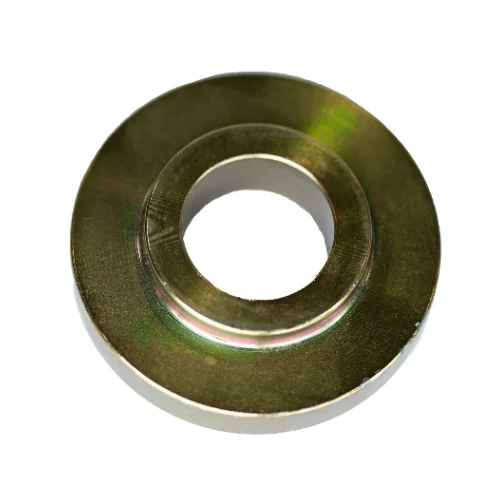

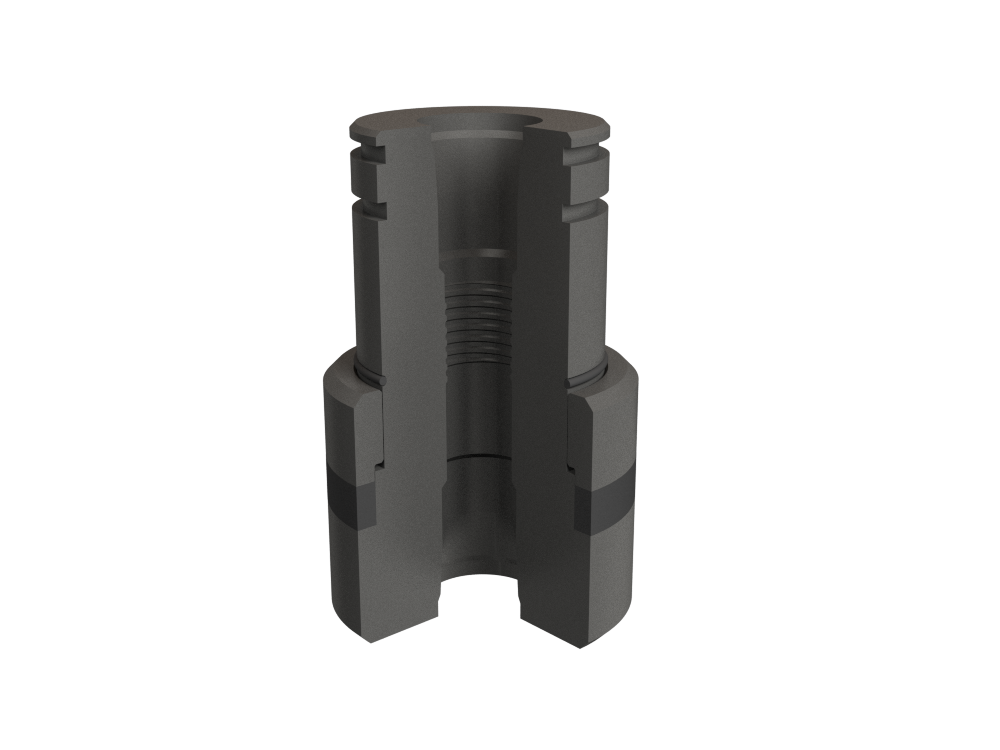

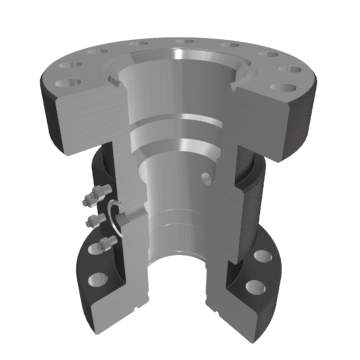

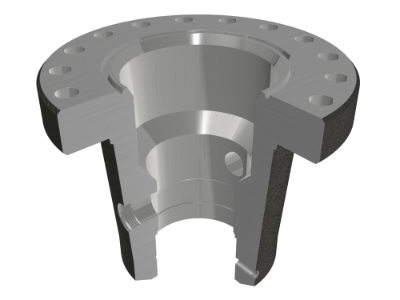

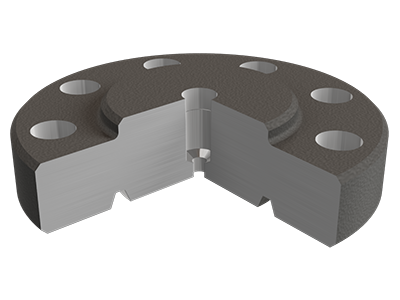

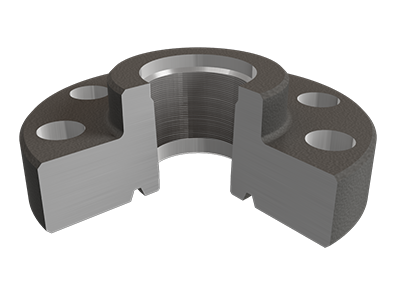

Gate Valve COMPONENTS

BODY GREASE FITTING

PACKING INJECTION FITTING

STEM ADAPTER

BEARING CAP

PACKING GLAND NUT

O-RINGS & SEALS

misc.COMPONENTS

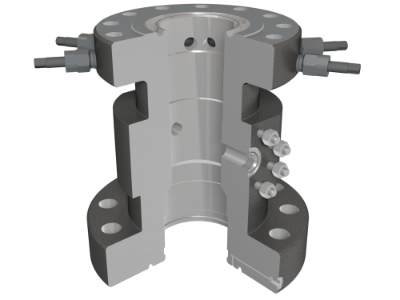

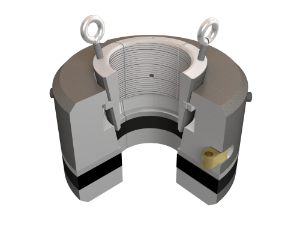

Wellhead AND TREE Equipment

Valveworks USA tree products are engineered and designed to ensure safety and reliability. Our experience, and extensive inventory means you can depend on Valveworks USA to deliver the wellhead solutions you need, when you need them.

FLOW IRON

Gate Valve Trim Chart

This tabbed chart displays Valveworks USA Service Condition Material Combinations and Trim Code Descriptions for various valve types. Includes corrosion ratings, trim codes, and material specifications for gates, seats, stems, bonnets, and bodies.

| Service Conditions | Trim | Body | Bonnet | Gate | Seat | Stem | BSR |

|---|---|---|---|---|---|---|---|

| General / Non Corrosive | AA | A487 4D/4130 | 4130 | 4130 | 4130 | 4130 | 1018 |

| General / Slightly Corrosive | BB | A487 4D/4130 | 4130 | 410SS | 410SS | 17-4SS | 316SS |

| General, Moderately Corrosive, CO2 | CC | CA6NM / 410SS | 410SS | 410SS | 410SS | 17-4SS | 316SS |

| Sour, Non-Corrosive | DD | A487 4D/4130 | 4130 | 4130 | 4130 | 4130 | 1018 ZINC |

| Sour, Non-Corrosive | DD-0,5 | A487 4D/4130 | 4130 | 4130 | 4130 | 17-4SS | 1018 ZINC |

| Sour, Slightly Corrosive | EE-0,5 | A487 4D/4130 | 4130 | 410SS | 410SS | 17-4SS | 316SS |

| Sour Highly Corrosive, MOD Abrasive, CO2 | EE-1,5 | A487 4D/4130 | 4130 | 410SS | 410SS | 410SS | 316SS |

| Sour Highly Corrosive, CO2, High Abrasive | EE | A487 4D/4130 | 4130 | 410SS | 410SS | NITRONIC 50*1 | 316SS |

| Sour, Moderately Corrosive, H2S | FF-0,5 | CA6NM / 410SS | 410SS | 410SS | 410SS | 17-4SS | 316SS |

| Sour, Highly Corrosive, CO2 and H2S | FF-1,5 | CA6NM / 410SS | 410SS | 410SS | 410SS | 410SS | 316SS |

| Sour, Highly Corrosive, CO2 and H2S | FF | CA6NM / 410SS | 410SS | 410SS | 410SS | NITRONIC 50*1 | 316SS |

| High Corrosion Extreme Service | HH-*3 | 4130 w/625 Inlay | 4130 w/625 Inlay | INCONEL® 718 *2 | INCONEL® 718 *2 | INCONEL® 718 *2 | 316SS |

- INCONEL® 718 IS AVAILABLE AS AN UPGRADE.

- INCONEL® 718 IS ONLY "NL" FOR TEMPERATURES K THRU U. INCONEL® 725 CAN BE USED UP TO TEMP X.

- CRA MATERIAL IS NOT AVAILABLE FOR TEMP Y SERVICE.

- STANDARD TRIM PARTS ARE QPQ NITRIDED.

- TUNGSTEN CARBIDE, HVOF, HARDFACED GATES AND SEATS ARE AVAILABLE FOR ANY TRIM UPON REQUEST.

| Trim Code | Material Class | Explanation |

|---|---|---|

| T-21 | AA | STANDARD TRIM - For essentially noncorrosive liquids or gases. Typical examples are crude and refined oils, natural or refined gases and processed hydrocarbons. Typical uses are wellheads, manifolds, flowlines and other similar installations requiring a through conduit valve. The temperature limitations are 0 degrees to 250 degrees F. |

| T-22 | BB | STAINLESS TRIM - For substantially the same service as T-21 but where the corrosion resistance of 13 Chrome Stainless Steel internal parts are desirable. Also usable for mildly corrosive fluids and gases when limited corrosion of the internal body surfaces can be tolerated. The temperature limitations are 0 degrees to 250 degrees F. Recommended when partial pressure of CO2 is greater than 30. |

| T-23 | CC | FULL STAINLESS TRIM - For any liquid or gaseous product for which the resistance of the 13 Chrome Stainless is adequate. Also used where the resistance of Stainless Steel is desirable from the standpoint of product purity. The temperature limitations are 0 degrees to 250 degrees F. Recommended when partial pressure of CO2 is greater than 30. |

| T-24 | EE | SOUR GAS AND OIL - Primarily for sour gas and oil where resistance to Hydrogen Sulfide embrittlement is required. Also suitable for other chemicals, products or hydrocarbons when H2S is present. May be used when CO2 is present in smaller amount than H2S. The temperature limitations are 0 degrees to 250 degrees F. |

| T-26 | FF | STAINLESS SOUR GAS AND OIL TRIM - Primarily for sour gas and oil when the CO2 content exceeds the H2S content. It is intended to provide resistance to the metal loss type of corrosion usually associated with CO2 plus resistance to Hydrogen Sulfide embrittlement. The temperature limitations are 0 degrees to 250 degrees F. |

| T-27 | WATERFLOOD (UNINHIBITED) - Primarily for use in untreated or uninhibited brackish saline water typically associated with oilfield waterflood projects and/or disposal wells in which the internal plastic coating of the body surfaces provides resistance to salt water corrosion. The internal parts are also resistant to Sulfide embrittlement and corrosion. The temperature limitations are 0 degrees to 250 degrees F. | |

| T-36 | AA | LOW TEMPERATURE – STANDARD TRIM – GENERAL OILFIELD - For essentially noncorrosive liquids or gases. Typical examples are crude and refined oils, natural or refined gases and processed hydrocarbons. Typical uses are wellheads, manifolds, flowlines and other similar installations requiring a through conduit valve. The temperature limitations are -50 degrees to 180 degrees F. |

| T-37 | EE | LOW TEMPERATURE -SOUR GAS AND OIL - Primarily for sour gas and oil where resistance to Hydrogen Sulfide embrittlement is required. Also suitable for other chemicals, products or hydrocarbons when H2S is present. May be used when CO2 is present in smaller amount than H2S. The temperature limitations are -50 degrees to 180 degrees F. |